Ensuring Safety: A Comprehensive Review of PPE Standards and Compliance

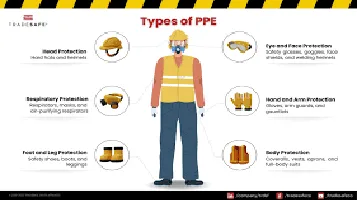

Personal Protective Equipment (PPE) standards and compliance are essential to ensuring the safety and health of individuals in various work environments. These standards are developed by organizations such as the Occupational Safety and Health Administration (OSHA) and the International Organization for Standardization (ISO) to provide guidelines on the design, production, and usage of protective gear. PPE includes items like helmets, gloves, goggles, and respiratory masks, which are designed to protect workers from hazards like chemical exposure, physical injury, and infectious diseases. Compliance with these standards ensures that the equipment meets minimum safety requirements, thereby reducing the risk of accidents and injuries. Regular training and inspections are crucial to maintaining compliance and ensuring that PPE is used effectively and safely in the workplace.

Introduction

Personal Protective Equipment (PPE) serves as a critical line of defense against various occupational hazards, ranging from chemical exposures and infectious diseases to physical injuries. The effectiveness of PPE in safeguarding workers largely hinges on stringent standards and compliance protocols. This review delves into the nuances of PPE standards and compliance, evaluating their role in enhancing workplace safety, the challenges faced in implementation, and the potential for future improvements.

The Importance of PPE Standards

PPE standards are established guidelines that ensure the quality, performance, and reliability of protective gear. These standards are often set by authoritative bodies such as the Occupational Safety and Health Administration (OSHA) in the United States, the European Committee for Standardization (CEN), and the International Organization for Standardization (ISO). The primary objective of these standards is to mitigate risks and protect workers from potential hazards.

For instance, OSHA’s PPE standards encompass a wide range of equipment, including helmets, gloves, goggles, and respiratory protection. These standards specify the requirements for design, construction, testing, and certification of PPE. By adhering to these guidelines, manufacturers can produce equipment that meets the necessary safety criteria, thereby ensuring that workers are adequately protected.

Compliance: The Backbone of Effective PPE Usage

While the establishment of PPE standards is crucial, compliance with these standards is equally important. Compliance involves not only the proper manufacturing of PPE but also its correct usage in the workplace. Employers are responsible for providing appropriate PPE to their employees and ensuring that it is used correctly. This includes training workers on the proper use, maintenance, and disposal of PPE.

One of the key aspects of compliance is regular inspection and maintenance of PPE. Equipment that is damaged or worn out can compromise safety, making it imperative for employers to conduct routine checks and replace PPE as needed. Additionally, proper record-keeping of PPE usage and training sessions can help organizations track compliance and identify areas for improvement.

Challenges in PPE Standards and Compliance

Despite the clear benefits of PPE standards and compliance, several challenges persist. One major challenge is the variability in standards across different regions and industries. For example, what constitutes acceptable PPE in one country may not meet the requirements in another. This lack of uniformity can create confusion and complicate the procurement process for multinational organizations.

Another significant challenge is ensuring that workers consistently use PPE. Factors such as discomfort, restricted movement, and inadequate training can lead to non-compliance. For instance, workers in high-heat environments may be reluctant to wear certain types of PPE due to the added discomfort. Addressing these issues requires a multifaceted approach, including the development of more ergonomic PPE designs and comprehensive training programs.

The COVID-19 pandemic has also highlighted the challenges of PPE shortages and supply chain disruptions. During the early stages of the pandemic, healthcare workers faced severe shortages of essential PPE, such as N95 masks and gloves. This underscored the need for robust supply chain management and the importance of having contingency plans in place.

Innovations and Future Directions

The field of PPE is continually evolving, with innovations aimed at improving both safety and user compliance. Advances in materials science have led to the development of lighter, more comfortable PPE that does not compromise on protection. For example, modern fabrics with moisture-wicking and antimicrobial properties can enhance comfort and reduce the risk of infections.

Technological advancements are also paving the way for smarter PPE. Integration of sensors and IoT (Internet of Things) technology can provide real-time monitoring of PPE usage and environmental conditions. These smart systems can alert workers and supervisors to potential hazards and ensure timely maintenance of equipment.

Furthermore, global harmonization of PPE standards could significantly streamline compliance efforts. International collaborations and agreements can help establish a unified set of standards, facilitating smoother operations for multinational organizations and ensuring consistent protection for workers worldwide.

Conclusion

PPE standards and compliance are fundamental to workplace safety, offering crucial protection against a myriad of occupational hazards. While significant strides have been made in establishing robust standards and promoting compliance, challenges such as variability in standards, user non-compliance, and supply chain disruptions persist. However, ongoing innovations and the potential for global harmonization of standards offer promising avenues for enhancement.

Ultimately, the efficacy of PPE lies in the collective efforts of manufacturers, employers, and workers. By fostering a culture of safety and prioritizing compliance, organizations can not only protect their workforce but also enhance overall productivity and morale. As we move forward, continued investment in research, training, and technological advancements will be key to overcoming existing challenges and ensuring the highest standards of occupational safety.