Review of Wood Finish: An In-Depth Examination

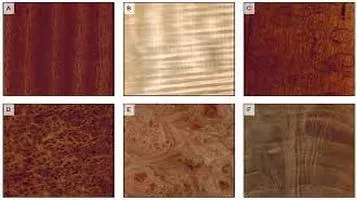

Wood finish refers to the application of a protective and decorative coating on wooden surfaces to enhance their appearance and durability. It serves both aesthetic and functional purposes, highlighting the natural beauty of the wood grain while providing a shield against environmental factors such as moisture, UV rays, and wear and tear. Common types of wood finishes include varnishes, oils, stains, lacquers, and polyurethane, each offering varying levels of sheen, color, and protection. The choice of finish depends on the intended use, desired look, and the type of wood being treated. Proper application of wood finish not only extends the life of wooden items but also enriches their texture and depth, making them more visually appealing and resilient to everyday use.

Wood finish is an essential component in woodworking, enhancing both the aesthetic appeal and durability of wooden surfaces. Whether you're a seasoned woodworker or a DIY enthusiast, understanding the various types of wood finishes and their applications can make a significant difference in your projects. In this review, we will explore the different types of wood finishes, their benefits, drawbacks, and some recommendations for choosing the right finish for your needs.

Types of Wood Finishes

Wood finishes can be broadly categorized into two main types: penetrating finishes and surface finishes.

Penetrating Finishes:

1. Oil Finishes:

- Linseed Oil: Derived from flax seeds, linseed oil is one of the most traditional wood finishes. It penetrates deeply into the wood, enhancing the grain and providing a warm, rich color. However, it can take several days to dry and may require multiple coats for optimal protection.

- Tung Oil: Extracted from the seeds of the tung tree, tung oil is prized for its water-resistant properties. It offers a durable, hard finish that enhances the wood's natural beauty. Tung oil can be more expensive and also requires a longer drying time.

- Danish Oil: A blend of oil and varnish, Danish oil provides the benefits of both penetrating and surface finishes. It’s easier to apply and dries faster than pure oils, making it a popular choice for many woodworkers.

2. Wax Finishes: Wax finishes provide a soft, natural look and feel. They are easy to apply and can be buffed to a sheen, but they offer limited protection against moisture and wear. Beeswax and carnauba wax are common choices.

Surface Finishes:

1. Varnish:

- Polyurethane Varnish: Polyurethane is one of the most durable finishes available. It forms a hard, protective layer on the wood surface, guarding against scratches, heat, and chemicals. Available in water-based and oil-based formulas, polyurethane can be challenging to apply without leaving brush marks or bubbles.

- Spar Varnish: Designed for exterior use, spar varnish is flexible and UV-resistant, making it ideal for outdoor furniture and marine applications. It’s more elastic than regular varnish, allowing it to expand and contract with temperature changes.

2. Shellac: Made from natural resin secreted by the lac bug, shellac provides a high-gloss finish and is known for its fast-drying properties. It’s easy to apply and repair, but it’s not very durable and can be damaged by water and alcohol.

3. Lacquer: Lacquer is a fast-drying finish that produces a clear, hard, and durable surface. It’s commonly used in commercial furniture production due to its quick drying time. Nitrocellulose lacquer is traditional, while newer acrylic lacquers offer better clarity and UV resistance.

4. Water-Based Finishes: These finishes have gained popularity due to their low odor and environmental friendliness. They dry quickly and provide a clear finish, but they may raise the wood grain, requiring additional sanding.

Benefits and Drawbacks

Each type of wood finish has its own set of advantages and disadvantages, making it crucial to choose the right finish based on your specific needs and project requirements.

Oil Finishes:

- Benefits: Enhance natural beauty, easy to apply, deep penetration.

- Drawbacks: Long drying time, may require frequent reapplication, limited protection against scratches and moisture.

Wax Finishes:

- Benefits: Simple application, natural look, easy to repair.

- Drawbacks: Limited durability, needs regular maintenance, not water-resistant.

Varnishes:

- Benefits: High durability, excellent protection against moisture and wear, available in various sheens.

- Drawbacks: Can be difficult to apply, longer drying time, potential for brush marks.

Shellac:

- Benefits: Fast drying, high-gloss finish, easy to repair.

- Drawbacks: Sensitive to water and alcohol, less durable.

Lacquer:

- Benefits: Quick drying, hard and durable finish, excellent clarity.

- Drawbacks: Requires proper ventilation, can be tricky to apply without spraying.

Water-Based Finishes:

- Benefits: Low odor, environmentally friendly, quick drying.

- Drawbacks: Can raise wood grain, sometimes less durable than oil-based finishes.

Recommendations

Choosing the right wood finish depends on several factors, including the type of wood, the intended use of the finished piece, and personal preference in terms of appearance and ease of application.

- For indoor furniture, oil finishes like Danish oil or polyurethane varnish are excellent choices due to their balance of durability and aesthetic appeal.

- For outdoor furniture, spar varnish or water-based exterior finishes provide the necessary protection against the elements.

- For quick projects or touch-ups, shellac and lacquer are ideal due to their fast-drying properties.

- When working on fine woodworking or restoration projects, consider traditional finishes like pure tung oil or shellac for their historical authenticity and beautiful finish.

Conclusion

Wood finishes play a crucial role in the final appearance and longevity of wooden pieces. Understanding the characteristics of different finishes allows you to make informed decisions and achieve the desired results in your woodworking projects. Whether it's the deep, warm glow of an oil finish, the robust protection of polyurethane, or the high-gloss elegance of shellac, there's a wood finish out there to suit every project and preference.